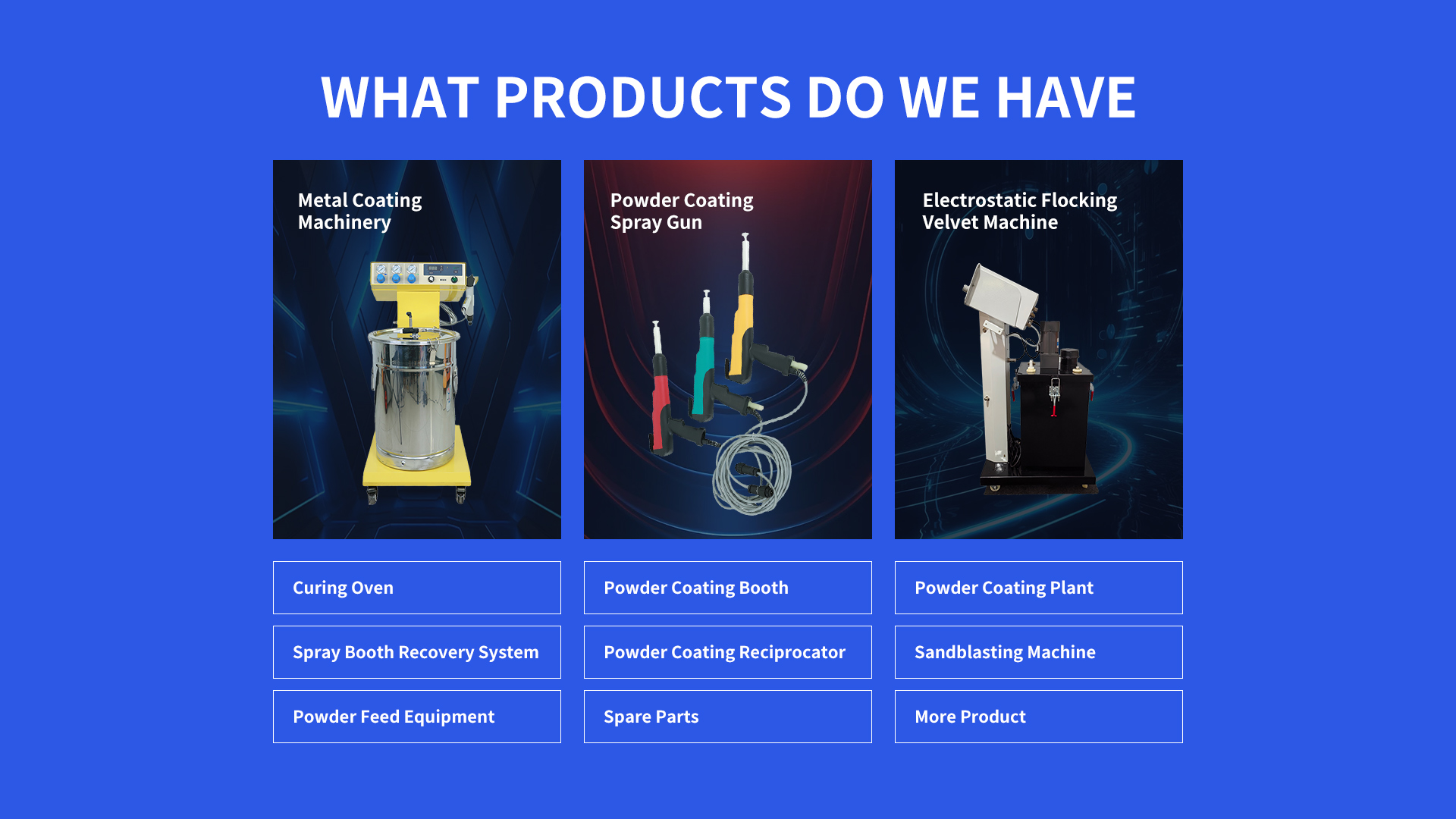

1. Powder Spraying Line for Sale Components and Structure

A Powder Spraying Line for Sale typically includes a pre-treatment station, electrostatic spray booth, conveyor system, curing oven, and powder recovery unit. Advanced lines integrate robotic arms for precision spraying, PLC controls for automation, and IoT sensors for real-time monitoring. Modular designs allow customization for high-volume production or specialized coatings like UV-resistant or anti-corrosive finishes.

2. Applications of Powder Spraying Line for Sale

These lines are used in automotive manufacturing (car bodies, wheels), appliance production (refrigerators, ovens), and architectural industries (aluminum profiles). They also serve aerospace components, agricultural machinery, and consumer electronics. Their ability to apply durable, eco-friendly coatings makes them essential for industries prioritizing quality and sustainability.

3. Powder Spraying Line for Sale Price Ranges

Manual lines start at 50,000,semi−automatedsystemsrangefrom150,000–500,000,andfullyautomatedlineswithroboticsexceed1 million. Pricing factors include line length (20–100 meters), throughput (100–1,000 parts/hour), and features like energy recovery or AI-driven quality control.

4. Best Practices for Operating Powder Spraying Lines

Surface Preparation: Degrease substrates and apply phosphate coatings for adhesion.

Spray Parameters: Set voltage (60–100 kV) and airflow (0.5–1.5 bar) based on part geometry.

Curing: Bake at 180–220°C for 10–25 minutes; use IR sensors for temperature accuracy.

Maintenance: Clean filters weekly, inspect nozzles daily, and recalibrate systems monthly.

5. How to Choose a Powder Spraying Line for Sale

Production Needs: Batch systems for low volume vs. continuous lines for mass production.

Automation Level: Opt for PLC-controlled systems with SCADA integration for data tracking.

Certifications: Ensure compliance with CE, OSHA, and NFPA 33 standards.

Energy Efficiency: Prioritize lines with heat recovery ovens and variable-speed conveyors.

6. Safety Protocols for Powder Spraying Lines

Ventilation: Install explosion-proof exhaust systems to reduce combustible dust risks.

Grounding: Maintain <1 ohm resistance to prevent electrostatic discharge.

PPE: Mandate NIOSH-approved respirators, anti-static suits, and safety goggles.

Fire Safety: Use CO2 suppression systems near powder storage areas.

7. Cost-Efficiency of Modern Powder Spraying Lines

Modern lines reduce energy consumption by 30% via heat recovery and IoT-driven optimizations. High overspray recovery rates (95%+) minimize material waste, while modular designs allow cost-effective upgrades. ROI is typically achieved within 2–3 years through reduced operational costs and increased throughput.

8. Key FAQs on Powder Spraying Lines for Sale

Q: What factors affect the price of a powder spraying line for sale?

A: Automation level, throughput capacity, and energy efficiency features significantly impact costs.

Q: Can powder spraying lines handle multi-color coatings?

A: Yes, with quick-clean systems and dedicated hoppers for rapid color changes.

Q: How to maintain a powder spraying line for sale?

A: Regularly replace filters, inspect electrical components, and update PLC software.

Q: Are these lines suitable for small businesses?

A: Compact, semi-automated powder spraying lines for sale are ideal for SMEs with limited budgets.

Q: What certifications ensure safety in powder spraying lines?

A: Look for CE, ATEX, and NFPA 33 compliance when purchasing equipment.

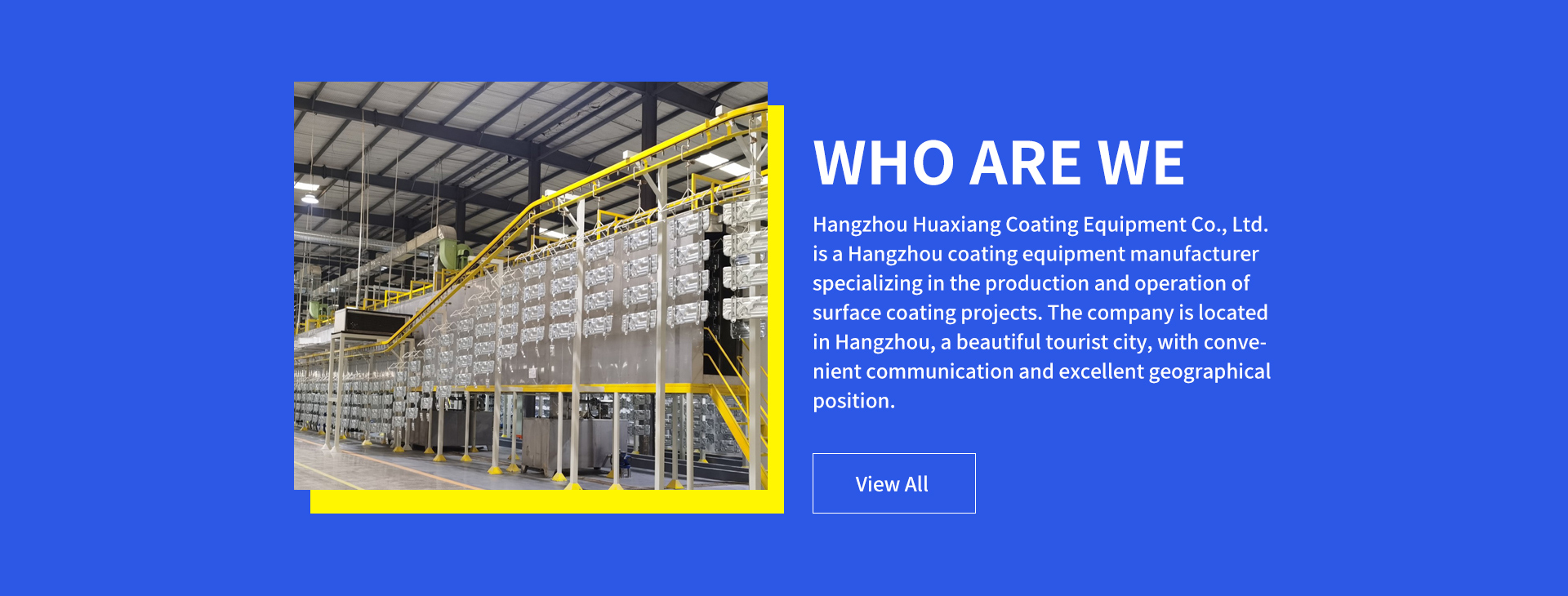

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com